Choosing the best grease for wheel bearings can significantly prolong their lifespan and ensure the smooth functioning of your vehicle. In this article, we will provide you with a guide to selecting the highest-quality grease for wheel bearings, describing the essential properties to consider, different types of grease, and their applications. Moreover, we will recommend some top-rated products currently in the market. By the end of this reading, you will be equipped with the necessary knowledge to make an informed decision on the most suitable grease for your wheel bearings.

Top-Rated Grease Products for Wheel Bearings

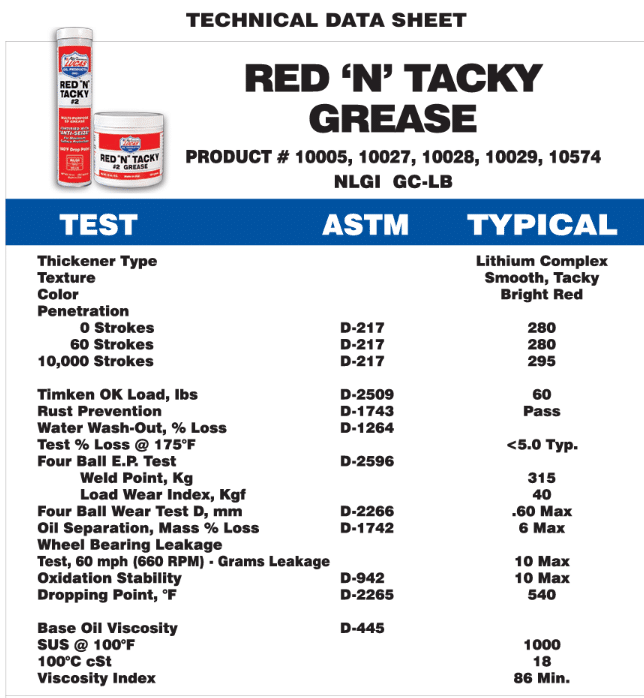

Navigating the world of wheel bearing greases can be complex, given the array of products on offer. Among them, Lucas Oil Red ‘N’ Tacky Grease, Royal Purple High Performance Grease, and AtomLube Ultra Heavy Duty Red Grease stand out, each providing unique benefits. Lucas Oil Red ‘N’ Tacky Grease excels in mechanical stability and water resistance, Royal Purple offers high-performance synthetic lubrication, and AtomLube is engineered for heavy-duty applications, extending the lifespan of commercial and industrial equipment.

Choosing the best grease for wheel bearings depends on your vehicle’s specific requirements. Therefore, it’s crucial to understand the vehicle’s needs, the environment in which it operates, and the specific demands on the wheel bearings before making a decision.

Lucas Oil 10005 Red ‘N’ Tacky Grease

[lasso id=”5445″ link_id=”2483″ ref=”amzn-lucas-oil-10005-red-n-tacky-grease-14-ounce” sitestripe=”true”]With countless options available in the market, identifying the right product for lubricating wheel bearings can often be a complex task. Lucas Oil Red ‘N’ Tacky Grease emerges as a top contender in this arena, thanks to its unique formulation and diverse application range. So, let’s delve deeper into why this product is excellent for wheel bearings.

Rust and Oxidation Inhibitors

One of the primary factors causing wheel bearing damage is corrosion. Lucas Red ‘N’ Tacky Grease is fortified with rust and oxidation inhibitors, providing an extra layer of protection to the bearings. This prevents premature wear and tear and extends the lifespan of the wheel bearings, ultimately resulting in reduced maintenance costs and improved vehicle performance.

Water Resistance

The ability to resist water is crucial for any wheel bearing grease, given the varied environments vehicles encounter. Lucas Red ‘N’ Tacky Grease exhibits excellent water resistance, maintaining its consistency and effectiveness even in wet conditions. This quality prevents the grease from washing out, ensuring long-lasting lubrication and protection for the wheel bearings.

Excellent Mechanical Stability

Stability under pressure and heat is a must for any grease used in wheel bearings. Lucas Red ‘N’ Tacky Grease demonstrates excellent mechanical stability, maintaining its structure under heavy loads and high temperatures. This stability ensures consistent lubrication, reducing friction and minimizing wear.

Versatile Applications

Lucas Red ‘N’ Tacky Grease is suitable for agricultural, automotive, and industrial applications. This versatility means it can be used effectively in a variety of wheel bearings, from those in small cars to heavy-duty agricultural and industrial vehicles.

Enhanced with Extreme Pressure Additives

The product is fortified with a high degree of extreme pressure additives, granting it a true Timken load much higher than other greases of this type. This feature enables Lucas Red ‘N’ Tacky Grease to withstand heavy loads for extended periods, making it especially good for sliding surfaces and open gears, components often found in close association with wheel bearings.

Royal Purple High Performance Grease

[lasso id=”5490″ link_id=”2484″ ref=”amzn-royal-purple-01312-nlgi-no-2-high-performance-multi-purpose-synthetic-ultra-performance-grease-14-5-oz” sitestripe=”true”]Royal Purple High Performance Grease, also known as Ultra-Performance Grease (UPG), stands out as a superior choice. Its unique formulation and proven record in demanding scenarios make it a highly effective solution for wheel bearings.

Enhanced Bearing Life and Reliability

UPG is a synthetic, aluminum-complex grease known to substantially increase bearing life and equipment reliability. These factors are vital for wheel bearings, ensuring smooth vehicle operation and reduced maintenance needs.

Smooth, Cool, and Quiet Operations

Royal Purple High Performance Grease promises smoother, cooler, and quieter running bearings. This results in reduced friction and wear, offering an efficient and noise-free drive.

Excellent Water Resistance

Wheel bearings can frequently encounter water, and thus, water-resistant grease is critical. UPG provides excellent water resistance, protecting against both emulsion and washout. This ensures persistent lubrication even in challenging environments.

High-Temperature Stability

Bearings, particularly wheel bearings, can become extremely hot due to friction. UPG is stable at high temperatures, maintaining its consistency and efficacy, thus providing continuous protection.

Outstanding Oxidation Resistance

UPG’s excellent oxidation resistance offers extended service life, creating a safety margin between lubrication intervals. This feature is particularly beneficial for wheel bearings, which often encounter harsh operating conditions and high temperatures.

In conclusion, Royal Purple High Performance Grease offers an array of benefits, from increased bearing life and stability under high pressure and temperature to excellent water and oxidation resistance. It’s not surprising that users employ it for various applications, including wheel bearings, appreciating its ease of use with both wheel bearing packers and grease guns. Its proven success in extreme scenarios makes it a trustworthy and highly recommended product for wheel bearing maintenance.

AtomLube Ultra Heavy Duty Red Grease: The Premium Choice for Heavy-Duty Wheel Bearings

[lasso id=”5479″ link_id=”2485″ ref=”amzn-atomlube-ultra-heavy-duty-red-grease-2-pack-of-14-oz-tubes-waterproof-lubricant-high-temp-grease-wheel-bearing-grease-for-semi-truck-accessories” sitestripe=”true”]The importance of a high-performance lubricant for heavy-duty, commercial, and industrial applications, like on-highway fleets and farm equipment, cannot be overstated. AtomLube Ultra Heavy Duty Red Grease, designed with extended chemomechanical durability in mind, stands out as an exceptional choice for such demanding scenarios.

However, note that the HD Red Grease is not recommended for small anti-friction bearings operating over 5000 rpm, indicating the product’s focus on heavy-duty applications. Let’s delve into why this product is ideal for wheel bearings in heavy-duty applications.

Extreme-Pressure Lubrication and Wear Protection

Heavy-duty applications, such as commercial and industrial wheel bearings, often experience extreme pressure, which can lead to accelerated wear and tear. AtomLube Ultra Heavy Duty Red Grease offers outstanding extreme-pressure lubrication, protecting against wear and significantly extending bearing life.

Excellent Oxidation and Corrosion Resistance

Exposure to harsh conditions can result in oxidation and corrosion of wheel bearings. This product, with its excellent oxidation and corrosion resistance, provides a protective layer, ensuring bearings remain in optimal condition for longer.

Superior Water Resistance

Given the varied environments heavy-duty applications encounter, a lubricant with superior water resistance is crucial. AtomLube Ultra Heavy Duty Red Grease retains its lubrication properties even when exposed to water, ensuring continuous protection for your wheel bearings.

Superior Stay-In-Place Power

Heavy-duty applications often involve severe operating conditions. AtomLube Ultra Heavy Duty Red Grease exhibits excellent stay-in-place power under such conditions, ensuring consistent lubrication and protection.

Versatility

Beyond wheel bearings, AtomLube HD Red Grease is suitable for a wide range of mechanical components and systems such as pins, couplings, pumps, and conveyors, adding versatility to its list of strengths.

In conclusion, AtomLube Ultra Heavy Duty Red Grease, with its robust formulation and superior performance features, emerges as an exceptional choice for wheel bearings in heavy-duty, commercial, and industrial applications. Whether it’s an on-highway fleet, heavy equipment, or farm machinery, AtomLube delivers reliability and superior performance that keep your operations running smoothly and efficiently.

Why is Grease Important for Wheel Bearings?

Before we delve into the specifics, it’s crucial to understand why wheel bearings require grease. Wheel bearings are vital components in your vehicle, ensuring a smooth and efficient ride. They reduce friction and heat, allowing your wheels to rotate smoothly. However, these components can wear out over time, especially without proper lubrication. This is where wheel bearing grease comes into play. It reduces friction, prevents excessive heat build-up, protects against rust and corrosion, and extends the overall lifespan of the bearings.

Types of Grease for Wheel Bearings

There are several types of wheel bearing grease available in the market, each with different properties suited for various applications.

Lithium Complex Grease

This is the most common type of wheel bearing grease. It offers excellent heat resistance, making it suitable for high-speed and high-temperature applications.

Calcium Sulfonate Grease

Known for superior water resistance, this grease type is excellent for vehicles frequently exposed to wet environments.

Polyurea Grease

This grease type has excellent oxidative and thermal stability, making it ideal for high-speed bearings.

Factors to Consider when Choosing Wheel Bearing Grease

When selecting the best grease for wheel bearings, consider the following factors:

Temperature Range

The grease should be able to withstand the heat generated by the bearings, especially at high speeds.

Water Resistance

The grease should not be easily washed away, particularly if the vehicle operates in wet conditions frequently.

Viscosity

Choose a grease that maintains its thickness under high-pressure conditions.

Load-Carrying Capacity

The grease should withstand the load applied to the bearings without breaking down.

Compatibility

Ensure the grease is compatible with the materials of your wheel bearings.

Best Grease for Wheel Bearings: FAQs

What is the role of grease in wheel bearings?

Grease in wheel bearings reduces friction, heat, and wear, thereby enhancing the lifespan and performance of the bearings. It also protects against contaminants and corrosion.

Are all greases suitable for wheel bearings?

No, not all greases are suitable for wheel bearings. The ideal grease for wheel bearings must be able to withstand high temperatures, resist water, and provide excellent wear protection.

How often should I grease my wheel bearings?

The frequency depends on your vehicle’s make and model, the type of grease used, and the driving conditions. However, a general rule is to check and, if necessary, replace the grease when rotating your tires (approximately every 5,000 to 7,000 miles).

Can I mix different types of grease for my wheel bearings?

As a general rule, it’s not advisable to mix different types of grease. Different greases may have incompatible thickeners or base oils, which can reduce their effectiveness.

Is synthetic grease better for wheel bearings?

Synthetic greases often perform well under extreme temperatures and pressures, providing extended protection compared to conventional greases. However, the best choice depends on the specific requirements of your vehicle and driving conditions.

What are the key features to look for in a wheel bearing grease?

Key features include high-temperature resistance, water resistance, good load-bearing properties, and corrosion prevention. Also, the grease should have a good ‘stay-in-place’ capability under the driving conditions.

How do I know if my wheel bearings need greasing?

Common signs that your wheel bearings may need greasing include a humming or rumbling noise from your wheels, poor steering control, uneven tire wear, or if it’s been a long time since the last greasing.

How do I apply grease to wheel bearings?

To apply grease, you’ll first need to remove the wheel and the hub or drum containing the bearings. Clean out the old grease, apply new grease to the bearings and the inside of the hub, then reassemble. If you’re unsure, consider getting a professional to do it.

What happens if I don’t grease my wheel bearings?

Without proper lubrication, wheel bearings can overheat and fail, leading to a loss of control of the vehicle, uneven tire wear, and potentially costly repairs. Regular greasing ensures smooth operation and longevity of your wheel bearings.

Is there a specific type of grease for front and rear wheel bearings?

Generally, the same type of high-quality, high-temperature grease can be used for both front and rear wheel bearings. However, always check your vehicle’s manual for any specific recommendations.

Does weather affect the type of grease I should use for my wheel bearings?

Yes, weather can influence your choice. In colder climates, a low-temperature grease ensures smooth operation, while high-temperature grease is preferable in warmer climates or for vehicles operating under high load or speed conditions.

When is it advisable to opt for professional wheel bearing service?

It’s recommended to choose professional service when you lack the necessary tools, skills, or confidence to perform the task accurately. Professional mechanics possess the expertise to ensure precise bearing maintenance.

DIY expenses mainly cover the cost of grease and any required tools. In contrast, professional service costs encompass labor, high-quality grease, and potential replacement parts. The inclusion of labor costs makes professional service generally more costly.