A clock spring is a crucial component in a car that plays a vital role in the functioning of multiple systems like cruise control, traction control, and the horn. It is located between the steering wheel and the steering column, allowing various buttons on the steering wheel to connect to the vehicle’s systems. The clock spring allows the steering wheel to turn smoothly without damaging the cables connected to it.

It also enables the horn to function and the airbag to deploy when necessary. Age, damage from car crashes, incorrect installation, and accidental damage during steering column repairs can cause a clock spring to fail. Symptoms of a broken clock spring include dead steering wheel buttons, traction control system warning light, airbag warning light, malfunctioning horn, and abnormal steering wheel behavior. To test the functionality of a clock spring, a multimeter can be used.

Key Takeaways

- A clock spring is an essential component for the proper functioning of multiple car systems like cruise control, traction control, and the horn.

- It connects the steering wheel to the vehicle’s systems, allowing for smooth steering wheel movement and the transmission of signals.

- Symptoms of a broken clock spring include dead steering wheel buttons, warning lights, malfunctioning horn, and abnormal steering wheel behavior.

- A multimeter can be used to test the functionality of a clock spring.

- If a clock spring is faulty, it needs to be replaced to ensure the safe operation of airbags and other systems.

What Is a Clock Spring?

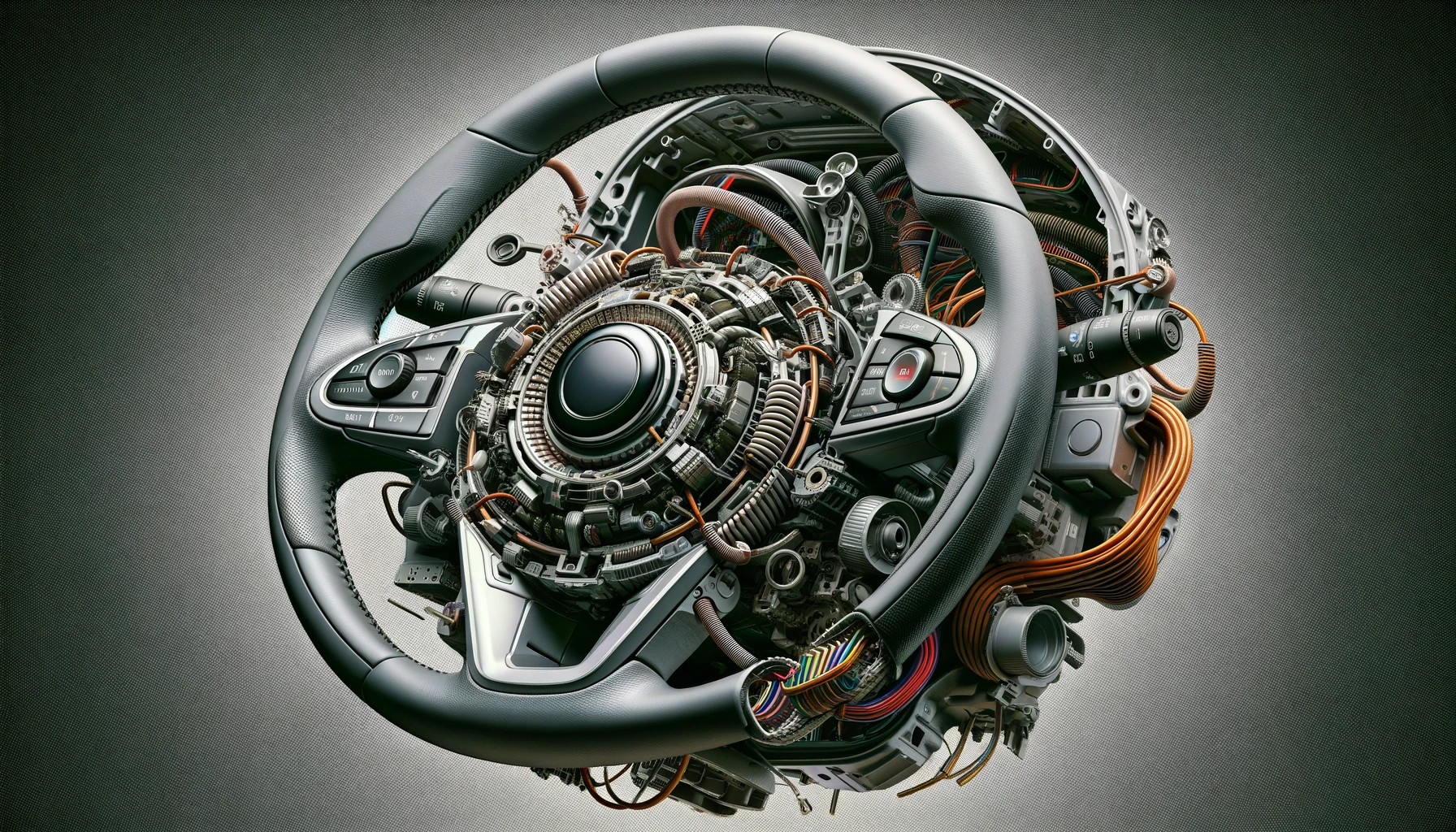

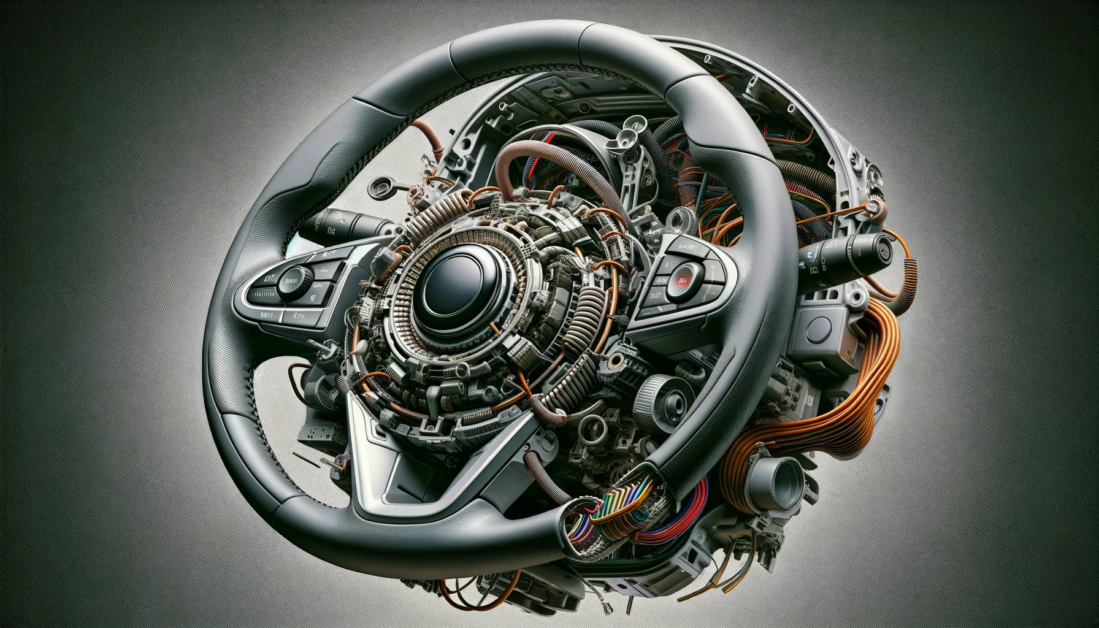

A clock spring, also known as a coil spring unit, spiral cable, or cable reel assembly, is an essential device in a car that connects the steering wheel to various electrical components. Its purpose is to allow the smooth rotation of the steering wheel without damaging the cables connected to it. The clock spring is located between the steering wheel and the steering column, ensuring the safe and efficient functioning of systems like cruise control, airbag deployment, and horn operation.

In simple terms, the clock spring acts as a connector between the steering wheel and the car’s electrical systems. It consists of a coiled wire that can rotate as the steering wheel turns. This rotation allows the various buttons on the steering wheel to connect to the vehicle’s systems, such as controlling the cruise control or activating the horn. Without a properly functioning clock spring, these essential functions would not work as intended.

The location of the clock spring between the steering wheel and steering column is crucial for its functioning. It is usually part of the same assembly as the turn signal lever, making it easily accessible. However, accessing the clock spring requires the removal of the steering wheel and the covers covering the steering wheel axle. This ensures that the clock spring is properly secured and can transmit the necessary signals from the steering wheel to the car’s electrical systems.

| Key Highlights | Details |

|---|---|

| Definition | A device that connects the steering wheel to electrical components |

| Purpose | To allow smooth rotation of the steering wheel without damaging cables |

| Location | Between the steering wheel and steering column |

How Does a Clock Spring Work?

A clock spring functions by using connectors to link the steering wheel buttons to various systems in a car. These connectors allow for the transmission of power through conductors inside the spring, enabling the buttons to control functions such as cruise control and radio volume. The clock spring also facilitates the rotation of the steering wheel without damaging the cables connected to it.

When the steering wheel is turned, the clock spring rotates along with it. This rotation allows the conductors inside the spring to maintain a continuous electrical connection while the steering wheel moves. If the conductors break, the clock spring will no longer be able to transmit power, resulting in the malfunctioning of the steering wheel buttons.

In summary, the clock spring’s connectors and rotation mechanism are essential for the transmission of power and the proper functioning of the steering wheel buttons in a car.

Key Points:

- The clock spring has connectors that link the steering wheel buttons to various systems in a car.

- When the steering wheel is turned, the clock spring rotates, maintaining a continuous electrical connection.

- If the conductors inside the clock spring break, the steering wheel buttons will malfunction.

Clock Spring Purpose

The clock spring serves several important purposes in a car. It facilitates the safe and reliable connection of cables between the steering wheel and the steering column, preventing them from breaking or becoming damaged when the steering wheel turns. This is crucial for ensuring smooth steering wheel movement and maintaining control of the vehicle.

Additionally, the clock spring plays a key role in the functioning of the car’s horn. It allows the signals from the buttons on the steering wheel to transmit to the car’s computer, activating the horn when necessary. Without a functioning clock spring, the horn may not work properly or may not work at all, potentially compromising safety on the road.

Furthermore, the clock spring is essential for the deployment of the airbag system. By transmitting signals from the steering wheel to the car’s computer, it enables the airbag to deploy promptly in the event of a collision or impact. A faulty clock spring can hinder the proper functioning of the airbags, compromising the safety of the driver and passengers.

| Function | Importance |

|---|---|

| Cable connection | Prevents cable breakage during steering wheel rotation |

| Horn function | Enables activation of the car’s horn through steering wheel buttons |

| Airbag deployment | Facilitates timely deployment of airbags in the event of a collision |

| Steering wheel movement | Ensures smooth and controlled steering wheel rotation |

Overall, the clock spring is a critical component in a car, responsible for various essential functions. Maintaining the proper functioning of the clock spring is vital for ensuring the safety and performance of the vehicle.

What Causes a Clock Spring Failure?

A clock spring can fail due to various reasons, leading to malfunctioning electrical components in a car. Understanding the causes of clock spring failure is crucial for maintaining the proper functioning of essential systems like the airbag, horn, and steering wheel buttons.

Age and Attrition

One of the main causes of clock spring failure is age and attrition. Over time, the clock spring can deteriorate due to wear and tear. However, with proper maintenance, clock springs generally last the lifetime of a vehicle.

Damage After a Car Crash

Damage to the clock spring can occur after a car crash, even if it is not immediately apparent. The impact from the collision can cause the clock spring to break or become misaligned, affecting its functionality.

Incorrect Installation

Incorrect installation of the clock spring is another common cause of failure. If the clock spring is already wound tight during installation, it can break immediately. It is crucial to follow the manufacturer’s instructions and ensure proper installation to avoid this issue.

Accidental Damage During Steering Column Repairs

Accidental damage during steering column repairs can also lead to clock spring failure. Mishandling or improper removal of the steering column can damage the clock spring, rendering it ineffective.

Understanding these causes of clock spring failure can help car owners take proactive measures to prevent such issues. Regular maintenance, proper installation, and careful handling during repairs can help prolong the lifespan of the clock spring and ensure the safe and efficient operation of electrical components in a vehicle.

| Clock Spring Failure Causes | Description |

|---|---|

| Age and Attrition | The clock spring can deteriorate over time due to wear and tear, although proper maintenance can extend its lifespan. |

| Damage After a Car Crash | Even if not immediately apparent, a car crash can cause the clock spring to break or become misaligned. |

| Incorrect Installation | If the clock spring is incorrectly installed, especially if it is already wound tight, it can break immediately. |

| Accidental Damage During Steering Column Repairs | Mishandling or improper removal of the steering column during repairs can lead to clock spring damage. |

Broken Clock Spring Symptoms

A broken clock spring in a car can lead to several noticeable symptoms. These symptoms can indicate that there is an issue with the clock spring and may require immediate attention to ensure the safe operation of the vehicle.

Dead Steering Wheel Buttons

One common symptom of a broken clock spring is when the buttons on the steering wheel stop working. This can include buttons for functions such as volume control, cruise control, and audio settings. When the clock spring is damaged, it can interrupt the electrical connection between the steering wheel buttons and the vehicle’s systems, resulting in inoperative buttons.

Traction Control System Warning Light

Another symptom of a broken clock spring is the illumination of the traction control system warning light on the dashboard. The clock spring is responsible for transmitting signals related to the vehicle’s traction control system, and when it fails, the warning light may turn on, indicating an issue with this system.

Airbag Warning Light

When the clock spring is damaged, it can also affect the proper functioning of the airbag system. If the clock spring fails, the airbag warning light on the dashboard may illuminate. This indicates that there is a problem with the clock spring, which can impact the deployment of the airbag in case of an accident.

Malfunctioning Horn

A faulty clock spring can also cause the horn to malfunction. If the clock spring is damaged, it may interrupt the electrical connection between the steering wheel button for the horn and the horn itself. As a result, pressing the horn button may not produce any sound, indicating a problem with the clock spring.

Abnormal Steering Wheel Behavior

Lastly, a broken clock spring can lead to abnormal steering wheel behavior. This can include rubbing or clicking sounds when turning the steering wheel. These unusual sounds can be an indication that the clock spring is damaged and no longer functioning correctly.

It is important to address these symptoms promptly if they arise, as a broken clock spring can impact the overall functionality and safety of the vehicle.

Can a Clock Spring Be Repaired?

In most cases, a clock spring cannot be repaired and needs to be replaced. The intricate design and internal wiring of the clock spring make it difficult to repair without compromising its functionality. Additionally, attempting to repair a clock spring can be time-consuming and may not guarantee a successful repair.

When a clock spring is defective or broken, it is crucial to replace it to ensure the proper functioning of essential safety features like airbags and horns. The replacement process involves removing the old clock spring and installing a new one. It is recommended to consult a professional mechanic or refer to the vehicle’s repair manual for guidance on the specific replacement procedure.

Table: Clock Spring Repair vs. Replacement

| Repair | Replacement |

|---|---|

| Challenging and time-consuming | Straightforward process |

| No guaranteed success | Ensures proper functionality |

| Potential compromises to safety | Preserves safety features |

| Risk of further damage | Fresh and reliable component |

Considering the critical role a clock spring plays in the safe operation of a vehicle, the replacement of a faulty clock spring is the recommended course of action. Clock springs are relatively inexpensive and widely available, making it a more practical and reliable solution compared to attempting repairs.

Where Is the Clock Spring Located in a Car?

The clock spring is a vital component in a car, but its location may not be immediately obvious. The clock spring is typically located in the steering column between the steering wheel and the steering column itself. It is often part of the same assembly as the turn signal lever. Accessing the clock spring for repairs or replacement requires removing the steering wheel and the covers that are covering the steering wheel axle.

Table: Clock Spring Location

| Car Component | Location |

|---|---|

| Steering Wheel | Front of the vehicle |

| Steering Column | Located beneath the steering wheel |

| Clock Spring | Between the steering wheel and the steering column |

The location of the clock spring is essential to understand for any maintenance or replacement procedures. It is crucial to follow proper procedures and exercise caution when working with the clock spring to avoid damage to the assembly or other components of the vehicle’s steering system.

Now that we have discussed the location of the clock spring, let’s move on to how to test its functionality and what role it plays with the airbag system.

How Do You Test a Clock Spring’s Functionality?

Testing the functionality of a clock spring is essential to ensure the smooth operation of various electrical components in a car. One way to test a clock spring is by using a multimeter. Here’s a step-by-step guide on how to perform the test:

- Set the multimeter to the Ohms setting.

- Connect the positive lead of the multimeter to the clock spring plug that connects to the airbag system.

- Connect the negative lead to one of the power supply pins in the backside port of the clock spring.

- Rotate the clock spring to simulate the movement of the steering wheel.

- Observe the readings on the multimeter. Inconsistent or infinite readings indicate a faulty clock spring.

By following this procedure, you can determine whether the clock spring is functioning properly or if it needs to be replaced. It is important to note that clock springs cannot be repaired and should be replaced if they are found to be faulty.

Table: Clock Spring Functionality Test Results

| Rotation | Multimeter Reading | Interpretation |

|---|---|---|

| Clockwise | 5 ohms | Normal |

| Counterclockwise | 10 ohms | Normal |

| Full Rotation | Infinite | Faulty Clock Spring |

As seen in the table above, a properly functioning clock spring should display consistent resistance readings in both clockwise and counterclockwise rotations. A reading of “infinite” indicates a faulty clock spring that needs to be replaced. It is recommended to consult a professional mechanic for accurate testing and replacement of a clock spring if necessary.

What Does the Clock Spring Do with an Airbag?

The clock spring plays a critical role in the deployment of the airbag. It is responsible for transmitting signals from the steering wheel to the car’s computer, which triggers the deployment of the airbag when necessary. When a collision or impact is detected, the car’s computer sends a signal to the clock spring, which then activates the airbag system.

The clock spring ensures that the necessary electrical connections between the steering wheel and the airbag system are maintained during steering wheel rotation. It allows the airbag to deploy effectively, protecting the driver and passengers in the event of an accident. Without a properly functioning clock spring, the airbag may not deploy correctly or may not deploy at all, posing a significant safety risk.

Understanding the Clock Spring-Airbag Connection

The clock spring is connected to the airbag system through electrical wiring, which enables the communication between the steering wheel and the car’s computer. It allows the steering wheel to rotate freely while maintaining the integrity of the electrical connections. Any disruption or damage to the clock spring can result in a loss of communication between the steering wheel and the airbag system, potentially compromising the effectiveness of the airbag deployment.

Regular maintenance and prompt replacement of a faulty clock spring are crucial for ensuring the safe operation of the airbag system. If any symptoms of a broken clock spring arise, such as a malfunctioning horn or airbag warning light, it is essential to have the clock spring inspected and replaced by a qualified professional.

| Common Clock Spring-Airbag Connection Issues: | Effects on Airbag Deployment: |

|---|---|

| Broken clock spring | Airbag may not deploy or may deploy incorrectly |

| Disrupted electrical connections | Airbag deployment can be delayed or inhibited |

| Faulty clock spring installation | Airbag system may not function properly |

| Worn-out clock spring | Intermittent or failed airbag deployment |

Ensuring the proper functioning of the clock spring-airbag connection is essential for the overall safety of the vehicle. Regular inspections, proper maintenance, and timely replacement of a faulty clock spring are vital steps in maximizing the effectiveness of the airbag system.

How to Replace a Clock Spring

Replacing a clock spring is a necessary task when the original component becomes damaged or faulty. Follow the step-by-step procedure below to ensure a smooth and successful clock spring replacement.

1. Disconnect the Negative Battery Cable

Before starting any work, it’s crucial to disconnect the negative battery cable to prevent any electrical accidents or malfunctions. Locate the battery in the engine compartment and use a wrench to loosen the nut securing the negative cable. Once loosened, remove the cable from the battery terminal.

2. Remove the Airbag and Steering Wheel

To access the clock spring, the airbag and steering wheel need to be removed. Consult the vehicle’s manual for detailed instructions on how to remove the airbag and steering wheel safely. Typically, this involves removing screws, disconnecting electrical connectors, and carefully pulling out the airbag and steering wheel components.

3. Disconnect the Old Clock Spring and Install the New One

Once the airbag and steering wheel are removed, locate the old clock spring attached to the steering column. Disconnect any electrical connectors or harnesses connected to the clock spring and carefully remove it from the steering column. Install the new clock spring by carefully aligning it with the steering column, ensuring all connectors are properly fitted.

Reassemble the airbag and steering wheel components in the reverse order of removal, following the vehicle’s manual instructions. Ensure all screws are tightened securely and all electrical connectors are properly connected.

Remember to reconnect the negative battery cable after completing the clock spring replacement. Test the functionality of the steering wheel buttons, horn, and any other systems connected to the clock spring to ensure proper operation.

| Step | Procedure |

|---|---|

| 1 | Disconnect the negative battery cable. |

| 2 | Remove the airbag and steering wheel. |

| 3 | Disconnect the old clock spring and install the new one. |

| 4 | Reassemble the airbag and steering wheel components. |

| 5 | Reconnect the negative battery cable. |

Can You Drive a Car with a Bad Clock Spring?

Driving a car with a bad clock spring is not recommended due to the potential safety risks involved. The clock spring is a crucial component that ensures the proper functioning of essential safety features, such as airbags and horns. A faulty clock spring may prevent airbags from deploying correctly, increasing the risk of injury during an accident. Additionally, a malfunctioning clock spring can lead to other electrical malfunctions, compromising the overall safety of the vehicle and its occupants.

When the clock spring fails, it can result in dead steering wheel buttons, malfunctioning horns, and the illumination of warning lights related to airbags or traction control systems. These symptoms indicate a problem with the clock spring and should not be ignored.

To ensure the safety of yourself and others on the road, it is crucial to address a bad clock spring promptly. Seek professional assistance to replace the faulty clock spring and restore the proper functioning of your vehicle’s safety systems. Ignoring the issue and continuing to drive with a defective clock spring can put you at a significant risk, compromising the overall safety of your car.

FAQ

What is a clock spring?

A clock spring is a crucial component in a car that connects the steering wheel to various electrical components, allowing for the smooth rotation of the steering wheel without damaging the cables connected to it.

Where is the clock spring located in a car?

The clock spring is located between the steering wheel and the steering column.

How does a clock spring work?

The clock spring has connectors that link the steering wheel buttons to the vehicle’s systems. It allows the buttons to transmit power through conductors inside the spring, enabling functions like cruise control, airbag deployment, and horn operation.

What is the purpose of a clock spring?

The clock spring ensures safe cable connection between the steering wheel and the steering column, enables the functioning of the horn and airbag deployment, and allows for smooth steering wheel movement.

What causes a clock spring failure?

Clock spring failure can be caused by age, damage from car crashes, incorrect installation, or accidental damage during steering column repairs.

What are the symptoms of a broken clock spring?

Symptoms of a broken clock spring include dead steering wheel buttons, traction control system warning light, airbag warning light, malfunctioning horn, and abnormal steering wheel behavior.

Can a clock spring be repaired?

In most cases, a clock spring cannot be repaired and needs to be replaced. Attempting to repair it can compromise the safety of the airbags.

How do you test a clock spring’s functionality?

A multimeter can be used to test the functionality of a clock spring. By connecting the multimeter to specific points, you can observe the readings and determine if the clock spring is faulty.

What does the clock spring do with an airbag?

The clock spring transmits signals from the steering wheel to the car’s computer, triggering the deployment of the airbag when necessary.

How do you replace a clock spring?

Replacing a clock spring involves disconnecting the battery, removing the airbag and steering wheel, disconnecting the old clock spring, and installing a new one.

Can you drive a car with a bad clock spring?

It is not recommended to drive a car with a bad clock spring as it can pose a safety risk. The clock spring is essential for the proper functioning of airbags and other safety features.