Choosing the right grease for ball joints is important for vehicle maintenance. Ball joints are key for smooth suspension movement. Still people often overlook their lubrication. High-quality grease can enhance your vehicle’s performance and make it last longer.

Summary List

- Top Pick Overall: Lucas X-TRA Heavy Duty Grease

- Runner-Up: Valvoline’s Full Synthetic Grease

- Top Alternative: Sta-Lube CRC Moly Graph

- Top Budget Pick: Lucas Red ‘N’ Tacky Grease

- Optimal for High Humidity Conditions: Lucas Oil Marine Grease

What are Ball Joints?

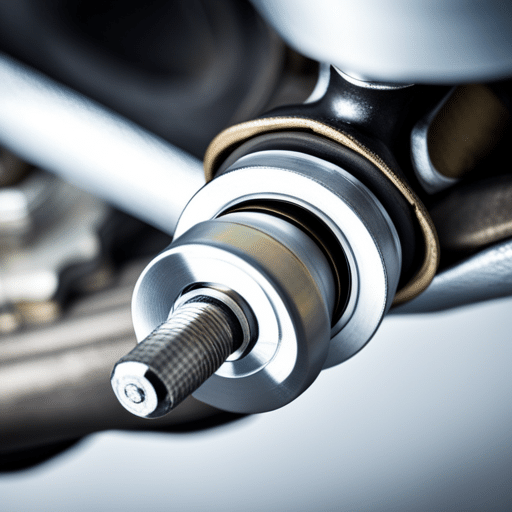

Ball joints are critical components of your vehicle’s suspension system. They act as pivot points between the wheels and the suspension, allowing for a wide range of movement in multiple directions. Think of them like the human hip joint, allowing for rotation and movement on several axes.

This flexibility is crucial for steering and wheel alignment, and it helps your vehicle navigate different road conditions, from bumps and potholes to turns and corners. Ball joints are usually found in the front suspension, with two joints per wheel, an upper and a lower one.

Top-Rated Grease Products for Ball Joints

Maintaining your vehicle’s performance necessitates choosing the right grease, with five top options being Lucas X-TRA Heavy Duty Grease, Valvoline’s Full Synthetic Grease, Sta-Lube CRC Moly Graph, Lucas Red ‘N’ Tacky Grease, and Lucas Oil Marine Grease.

Top Pick Overall: Lucas Oil Heavy Duty Grease

Resilient to high temperatures and remaining pliable in extremely low temperatures, Lucas X-TRA Heavy Duty Grease exceeds OEM specifications and is fortified with extreme pressure additives.

Crafted for a wide range of applications including automotive, agricultural, heavy-duty, and industrial uses, Lucas X-TRA Heavy Duty Grease boasts superior stability compared to standard lithium grease. Its virtual waterproof nature and extreme pressure additive package exceed the specifications of OEM Lube for Life, making it an exceptional choice for diverse applications.

Lucas Oil Heavy Duty Grease has earned rave reviews from users for its exceptional performance in severe climate conditions, particularly when used for lubricating ball joints. Users have observed that the grease remains in place without squeezing out, washing out, or drying out. The unique green color of the grease allows for easy detection of fresh application.

This grease has proven its effectiveness not just in automotive applications, but also in other equipment that involves moving parts. It has withstood high levels of heat and abuse without the need for constant reapplication. Several users have mentioned not needing to add any more grease to the fittings months after initial application on their ball joints.

Lucas Oil’s reputable track record adds to the assurance of this product’s quality. It has been highly recommended for anyone in need of a reliable lubricant, having shown excellent results after being used on newly changed ball joints in vehicles and even sway bar link ball joints. Overall, Lucas Oil Heavy Duty Grease remains our top pick for lubricating ball joints.

Runner-Up: Valvoline Moly-Fortified Gray Full Synthetic Grease

Valvoline Moly-Fortified Gray Full Synthetic Grease stands as a solid runner-up choice for ball joint lubrication, particularly in instances where Lucas Oil Heavy Duty Grease is not available. This synthetic grease has proven to be effective for a range of applications including ball joints.

As a multi-purpose solution, Valvoline Full Synthetic Grease is ideal for both automotive and industrial applications under extreme temperatures. Here are some additional benefits of this product:

- Reinforced with moly for enhanced film strength

- Fortified to withstand extreme pressure

- Formulated to prevent rust and oxidation

- Classified as NLGI #2 GC-LB lithium complex EP Grease for high performance

However, some users have raised concerns about the product’s long-term stability. Instances of the grease separating and the liquid portion leaking out over time have been reported, leading to apprehension about its performance in wheel bearings and ball joints. This concern is particularly pronounced in situations where the grease is subjected to the elements and under constant load.

Nonetheless, there are still numerous satisfied users who vouch for its performance in high-demand situations, such as lubricating upper control arm ball joints and in vehicles with high mileage. Many praise its ability to remain thick and sticky, providing good coverage and resisting hardening or drying over time.

In conclusion, while Valvoline Moly-Fortified Gray Full Synthetic Grease may not be the first choice for everyone, it still garners considerable support for its ability to handle a range of applications. It is especially recommended for users who prefer synthetic products and trust in Valvoline’s longstanding reputation in the industry.

Top Alternative: Sta-Lube CRC Moly-Graph Grease Extreme Pressure

Looking for a versatile and durable option for your ball joints? Sta-Lube CRC Moly Graph is our top alternative pick. The grease offers decent versatility and proves to be highly durable, making it a great all-around option. While some users have noted some separation when stored in temperature extremes, a simple stir makes it ready for use again.

Users appreciate its long-lasting characteristics, emphasizing that it’s their go-to choice for all their ball joint maintenance needs. Although some users find it to be on the pricier side, the consensus is that you get what you pay for.

In summary, Sta-Lube CRC Moly Graph offers a cost-effective balance of reliability and performance, making it a wise investment for your ball joint maintenance needs.

Top Budget Pick: Lucas Red ‘N’ Tacky Grease

Lucas Red ‘N’ Tacky Grease represents an affordable and effective solution for ball joint lubrication needs. This lithium complex grease, renowned for its smooth and tacky texture, is fortified with rust and oxidation inhibitors. It distinguishes itself with commendable water resistance and washout properties, excellent mechanical stability, and a great storage life.

It’s designed to withstand heavy loads over extended periods, and finds usage across agricultural, automotive, and industrial applications. The grease contains a high degree of extreme pressure additives, resulting in a superior timken load compared to other greases in this category. This makes it particularly suitable for sliding surfaces and open gears.

The distinctive red color and stickiness are often seen as beneficial, providing clear visual indication during replacement and ensuring that it stays where it is applied. Nevertheless, some users have reported issues with the grease breaking down and leaking out, a consideration to bear in mind. As a budget pick, Lucas Red ‘N’ Tacky Grease offers a good balance of cost and performance.

Optimal for High Humidity Conditions: Lucas Oil Marine Grease

Lucas Oil Marine Grease is a heavy-duty lithium complex grease known for its versatility. This product, backed by a unique additive system, finds use in multiple scenarios – from trailers to chassis lubrication, to automotive wheel bearings and outboards.

In marine applications, it exhibits noteworthy moisture resistance. This makes it a viable option for those who live in high-humidity, snowy, or coastal regions, or for applications where the vehicle is frequently exposed to water.

While this grease has clear benefits for those in moist environments, it’s important to consider your specific needs and conditions when choosing a lubricant for ball joints. Lucas Oil Marine Grease, with its NLGI GC-LB certification and application versatility, can be a suitable choice for some users, particularly those dealing with excess moisture.

Why Proper Lubrication Matters for Ball Joints

The importance of proper lubrication for ball joints cannot be overstated. Adequate lubrication ensures the longevity of these components and enhances their performance. It prevents premature wear and tear, reducing the likelihood of squeaks, squeals, or other undesirable noises while driving. Moreover, smooth operation of ball joints is integral to your vehicle’s suspension, affecting ride comfort and handling.

How Often Should You Grease Ball Joints?

The frequency of greasing your ball joints can depend on several factors, including the type of vehicle, the conditions in which you drive, and the specific recommendations of the vehicle manufacturer. However, a general rule of thumb is to grease the ball joints every time you change your oil, which is typically every 3,000 to 5,000 miles. If you regularly drive in harsh conditions – such as on dirt or gravel roads, in heavy traffic, or in extreme weather – you may need to grease the ball joints more frequently. Always refer to your vehicle’s owner’s manual for specific guidance.

Key Features to Consider When Choosing Grease for Ball Joints

When selecting the best grease for your vehicle’s ball joints, several factors come into play:

Viscosity

This refers to the thickness of the grease. High-viscosity grease tends to stay put and provides excellent lubrication but may be difficult to apply in cold weather. Low-viscosity grease is easier to apply but may not provide the same level of protection.

For most automotive applications, a grease with an NLGI grade of 2 and a moderately high-viscosity base oil is a good general-purpose choice. However, the specific requirements of the application, such as the load on the joint, operating temperatures, and exposure to contaminants like water or dust, might necessitate a different choice.

Temperature Tolerance

Consider the temperature range in which the grease will perform optimally. Some greases can withstand high temperatures without breaking down, making them suitable for high-performance or heavy-duty vehicles.

Ball joints, as integral components of a vehicle’s steering and suspension system, are subject to a variety of operating conditions, including temperature variations.

Grease must be able to perform and maintain its lubricating properties over the entire range of temperatures that the ball joints will experience. If the grease becomes too thin at high temperatures, it won’t provide an adequate lubricating film, leading to increased wear. If the grease becomes too thick or even solid at low temperatures, it won’t flow adequately into the spaces it needs to lubricate, leading to insufficient lubrication and potential damage.

Resistance to Water and Contaminants

Choose a grease that repels water and resists dust and dirt. This will protect the ball joints from corrosion and premature wear.

Marine Grease

It’s worth noting that the exposure to saltwater, especially, can be incredibly harsh on mechanical parts. Salt can accelerate corrosion processes, damaging metal components quickly. Marine grease is often formulated to resist this salt-induced corrosion, offering an extra layer of protection for these critical components.

[lasso id=”5447″ link_id=”2309″ ref=”amzn-lucas-oil-multi-purpose-marine-grease-14-oz” sitestripe=”true”]Marine grease would be an excellent choice for vehicles or equipment that are frequently exposed to water or operate in wet conditions. This is because the ball joints, which act as pivot points between the suspension and wheels, are crucial for smooth steering and handling. Exposure to water can lead to corrosion and premature wear, leading to decreased performance and eventual failure.

Remember, while marine grease does offer excellent water resistance, it might not be as effective in high-temperature applications or under heavy loads, as some other greases are. It’s always essential to understand the specific needs of the application before deciding on the best lubricant.

Finally, marine grease may not mix well with other types of grease, especially those based on lithium. Mixing incompatible greases can lead to a significant reduction in lubricating performance, as they can coagulate, thin out, or otherwise change their properties. Therefore, if you are switching to marine grease from another type, it’s important to remove as much of the old grease as possible.

Compatibility

Ensure the grease is compatible with your vehicle’s specifications. Always check your owner’s manual or consult with a professional if in doubt.

Compatibility is a critical factor to consider when choosing a grease for ball joints, or any other application. Here’s why:

Chemical Compatibility

Not all greases are chemically compatible with each other. Some types of grease, when mixed, can cause changes in consistency and drop in performance. For instance, if you mix a lithium complex grease with a calcium or aluminum complex grease, it could cause the mixture to harden or even liquify, both of which could lead to inadequate lubrication. In severe cases, incompatible greases can cause mechanical damage.

Material Compatibility

Greases can also contain additives that may not be compatible with certain materials used in the construction of the ball joints. Some anti-wear or extreme pressure additives can corrode yellow metals, while some types of synthetic greases may not be compatible with certain rubber or plastic seals. Compatibility with the materials in your ball joints is crucial to prevent accelerated wear and potential failure.

Performance Compatibility

Different greases have different performance characteristics. Some are designed to perform better at high temperatures, some at low temperatures, some are designed for high-speed applications, while others are designed for high-load applications. Choosing the right grease for the operating conditions is essential for long service life and optimum performance.

Application Compatibility

Greases are designed with specific applications in mind. A grease that works well in a wheel bearing might not be suitable for a ball joint. This is due to different types of mechanical stresses, speeds, temperatures, and exposure to contaminants.

It is always advisable to consult the manufacturer’s guidelines, or consult with a lubrication specialist before selecting a grease for your ball joints. If changing grease types, it’s important to clean out the old grease as thoroughly as possible to prevent any compatibility issues.

How to Apply Grease to Ball Joints

[lasso id=”5450″ link_id=”2310″ ref=”amzn-utool-grease-gun-8000-psi-heavy-duty-pistol-grip-grease-gun-kit-with-14-oz-load-18-inch-resin-flex-hose-2-basic-coupler-2-extension-rigid-pipe-and-1-sharp-type-nozzle” sitestripe=”true”]Proper application of grease to your vehicle’s ball joints is just as important as choosing the right product. You’ll need a grease gun, the grease of your choice, and safety gear (gloves and safety glasses).

- Locate the grease fitting on the ball joint. This is a small, round nipple where the grease gun attaches.

- Attach the grease gun to the fitting.

- Pump the grease gun until the grease begins to ooze out of the ball joint. Do not overgrease, as this can lead to pressure build-up.

- Wipe away any excess grease.

- Repeat the process for all ball joints on your vehicle.

- Always remember to follow safety precautions and refer to your vehicle’s owner’s manual for specific instructions.

Key Factors to Consider When Buying a Grease Gun for Greasing Ball Joints

Grease guns are indispensable tools for vehicle maintenance, especially when it comes to greasing ball joints. When selecting the right grease gun for this task, you must consider several factors to ensure that the tool fits your needs. These include the type of grease gun, ease of use, pressure, and capacity.

Type of Grease Gun

Lever, Pistol-Grip, or Pneumatic?

There are three main types of grease guns: lever-operated, pistol-grip, and pneumatic. Lever-operated guns are the most basic type, requiring two hands to operate. Pistol-grip guns can be operated with one hand, leaving your other hand free. Pneumatic guns, powered by air pressure, provide the easiest operation and are great for heavy-duty work but are also the most expensive.

Ease of Use

User-friendly Operation and Maintenance

Choose a grease gun that’s easy to load, operate, and clean. The tool should feel comfortable in your hand, and it should be simple to control the flow of grease. Consider a model with a non-slip grip and an easy-to-use plunger for reloading the grease.

Pressure

Ensuring Adequate Lubrication

The pressure that a grease gun can generate is important because it determines how effectively the tool can push grease into the ball joint. For ball joints, which are typically tight spaces, you’ll need a grease gun that can deliver high pressure to ensure the grease adequately penetrates the joint.

Capacity

Matching Workload and Frequency

Consider how often you plan to use the gun and the number of ball joints you’ll be greasing. If you’re only greasing a couple of ball joints on one car, a smaller-capacity grease gun may suffice. For more intensive use, like in a professional garage setting, a larger-capacity model would be more suitable.

Cost Ranges for Different Types of Grease Guns

The cost of a grease gun can vary widely depending on the type, capacity, and features. Below, we’ll explore the typical price ranges for lever-operated, pistol-grip, and pneumatic grease guns.

Lever-Operated Grease Guns

Cost-Effective and Reliable

Lever-operated grease guns are the most basic type and are also the most affordable. Generally, you can expect to pay anywhere from $20 to $50 for a lever-operated grease gun. These are reliable tools for occasional use and simple tasks, making them an economical choice for most DIY enthusiasts.

Pistol-Grip Grease Guns

Versatile and User-Friendly

Pistol-grip grease guns offer the convenience of one-handed operation, which can make them a bit pricier. The typical price range for a pistol-grip grease gun falls between $30 and $100. The increased cost brings added ease of use and versatility, making these tools a favorite among many auto repair hobbyists and professionals alike.

Pneumatic Grease Guns

High-Capacity and High-Power

For the most demanding tasks or for professional settings, pneumatic grease guns are the preferred option. They’re powered by air pressure, which allows for easy operation and high-capacity greasing. As a result, they are also the most expensive. You can expect to pay anywhere from $100 to over $300 for a pneumatic grease gun, depending on its specific features and capabilities.

When budgeting for a grease gun, keep in mind the type of work you’ll be doing, how often you’ll use the tool, and the features that are important to you. Whether you’re an occasional DIYer or a professional mechanic, there’s a grease gun out there that fits both your needs and your budget. Remember, investing in a high-quality, appropriate tool can save you time, effort, and ultimately, money in the long run.

Understanding Vehicles with Ball Joints: Who Needs Grease?

If you’re contemplating the best grease for ball joints, it’s crucial to know what types of vehicles use ball joints in their suspension systems. Ball joints are commonly found in automobiles, but their application is not limited to just one type of vehicle. Below we explore the types of vehicles that typically incorporate ball joints in their design.

Types of Vehicles with Ball Joints

- Passenger Cars: Almost all modern cars use ball joints in their front suspension systems and, in some cases, in the rear suspension as well.

- Trucks and SUVs: Due to their heavier build and off-road capabilities, trucks and SUVs also use robust ball joints for better handling and load-bearing.

- Commercial Vehicles: Buses and some larger commercial trucks often incorporate ball joints for added maneuverability and weight distribution.

- All-Terrain Vehicles (ATVs): These vehicles require a high degree of maneuverability, making ball joints an essential component.

- Motorcycles: Some advanced motorcycle suspension systems use ball joints for enhanced road handling.

- Military Vehicles: Rugged military vehicles designed for difficult terrains also use ball joints for enhanced steering and weight distribution capabilities.

- Farm Machinery: Equipment like tractors can also incorporate ball joints to deal with the uneven terrains of agricultural fields.

Additional Types of Vehicles and Equipment with Ball Joints

- Towing Trucks: Tow trucks often use ball joints in their mechanisms for hoisting and moving other vehicles, as they require a high degree of flexibility and strength.

- Trailers and RVs: Ball joints can be found in the hitch systems of some trailers and RVs, particularly those that need to pivot in multiple directions.

- Boat Trailers: These trailers often employ ball joints to handle the uneven terrains they encounter, particularly when launching or retrieving a boat at a ramp.

- Utility Trailers: Trailers used for hauling heavy loads like construction equipment, farm machinery, or other utility vehicles also utilize ball joints to withstand the stresses and strains involved.

- Fifth-Wheel Trailers: These specialized trailers attach to a truck via a hitch in the truck bed and may use ball joints in their suspension and steering systems to enhance mobility.

- Articulated Trailers: Trailers that carry oversized loads sometimes use articulated systems that incorporate ball joints for better flexibility and movement.

In the towing and trailer world, the need for robust, flexible, and reliable ball joints is equally critical. These applications demand high-quality grease to ensure that the ball joints operate smoothly under varying load conditions, thereby extending their lifespan and ensuring safe and efficient operation.

Frequently Asked Questions about Ball Joint Grease

Q: Can I use any type of grease for my ball joints?

A: Not all greases are created equal. It’s important to use a high-quality, high-viscosity grease designed for automotive applications. The grease should have good temperature tolerance and resistance to water and contaminants. Always check your vehicle’s owner’s manual or consult a professional to ensure you’re using the correct grease.

Q: How can I tell if my ball joints need greasing?

A: Signs that your ball joints may need greasing include a creaking or squeaking noise when the suspension moves, difficulty steering, uneven tire wear, or a wandering steering wheel. If you notice any of these signs, it’s a good idea to have your ball joints inspected and greased as soon as possible.

Q: Can overgreasing damage the ball joints?

A: Yes, overgreasing can potentially cause damage. When too much grease is applied, it can create pressure that may damage the ball joint seals, leading to grease leakage and the potential for premature wear and tear.

Q: What happens if I don’t grease my ball joints?

A: Neglecting to properly grease your ball joints can lead to increased friction, accelerated wear and tear, and potentially, failure of the ball joints. This can affect your vehicle’s handling and safety, and it may lead to more costly repairs down the line. Regular greasing is a simple maintenance task that can greatly extend the life of your ball joints.

Q: Is it possible to replace the grease in my ball joints, or do I have to replace the entire joint?

A: If your ball joints are designed to be serviceable, they feature grease fittings that allow you to add grease as needed. However, if the ball joints are sealed and don’t have a grease fitting, they cannot be regreased and must be replaced once they wear out.

Q: What’s the difference between a sealed and a serviceable ball joint?

A: Sealed ball joints come lubricated from the factory and are designed to be maintenance-free for their entire service life. When they wear out, they need to be replaced. On the other hand, serviceable ball joints have a grease fitting, allowing for regular maintenance and prolonging their lifespan.

Q: Is there a specific type of grease for upper and lower ball joints?

A: Typically, the same type of high-quality, high-viscosity automotive grease can be used for both upper and lower ball joints. Always refer to your vehicle’s owner’s manual or consult with a professional for specific recommendations.

Q: Can I grease the ball joints myself, or should I take my car to a mechanic?

A: Greasing ball joints is a relatively straightforward process that can be done at home with the right tools and some basic knowledge. However, if you’re not comfortable doing it yourself or if you’re unsure about the process, it’s always best to take your vehicle to a professional to ensure the job is done correctly.

DIY greasing costs are limited to grease and potential tool purchases. Professional services include labor, quality grease, and any needed replacements. Prices vary, but professional servicing can cost significantly more due to labor expenses.

Q: Does driving in harsh conditions affect how often I need to grease my ball joints?

A: Yes, driving in harsh conditions, such as on dirt or gravel roads, in heavy traffic, or in extreme weather, can lead to faster wear and tear on your ball joints. If you regularly drive in such conditions, you may need to grease your ball joints more frequently to maintain optimal performance.

Q: Can you grease a ball joint without a grease gun?

While a grease gun is the preferred method for greasing a ball joint, it is possible to do it without one. You can use a hand-operated grease tube or even apply the grease manually using a flat tool like a spatula. However, these methods are less effective at distributing the grease evenly and may not penetrate as deeply, potentially compromising the lifespan and effectiveness of the ball joint.